The process of working with stainless steel is essential in industrial and architectural design, impacting our methods of construction and creation. This versatile material and its associated techniques offer numerous benefits, making it a preferred choice for various applications.

The Essence of Stainless Steel Sheet Metal Fabrication

The process of fabricating stainless steel involves various techniques such as cutting, bending, welding, and finishing to transform raw sheets into finished products. This procedure is crucial across numerous industries due to the remarkable properties of the material. Because of its exceptional resilience and resistance to corrosion, stainless steel is the perfect material for settings where strength and endurance are crucial. Diverse alloys provide differing levels of strength, corrosion resistance, and formability, enabling customized solutions to satisfy particular needs. After selecting the appropriate alloy, the metal sheets undergo shaping and cutting procedures. These processes ensure that the material is prepared to meet the precise requirements for its intended application.

Benefits of Using Stainless Steel in Fabrication

Many different industries widely use stainless steel sheet metal fabrication due to its many benefits. The material’s resistance to corrosion and rust is one of its main advantages. The strength-to-weight ratio of the material is another noteworthy advantage. Stainless steel is a material that is highly suitable for applications that require structural support without adding excessive weight because of its remarkable strength and relatively lightweight. This feature is very valuable in the construction, automotive, and aerospace industries. It is impossible to ignore the aesthetic attractiveness of stainless steel. It is a popular option for consumer goods and architectural features due to its clean and contemporary design. The material’s resistance to tarnishing and capacity to preserve its polish ensures the maintenance of product aesthetics over time.

Applications Across Industries

The versatility and utility of stainless steel sheet metal fabrication are demonstrated by the wide range of industries in which it finds application. Stainless steel is utilized in the building industry for architectural features, cladding, and structural elements. It is a popular material for building railings, staircases, and facades because of its low care requirements and durability. The manufacturing sector uses stainless steel to produce a range of machinery and equipment. Because of its resistance to corrosion and cleanliness, stainless steel is an ideal material for equipment that needs to adhere to strict hygiene requirements, which is appropriate in food processing and chemical processing. Stainless steel manufacturing offers additional benefits to the automobile sector. Exhaust systems, trim pieces, and structural parts use stainless steel because it can withstand high temperatures and doesn’t corrode when exposed to chemicals found on roads or in the environment.

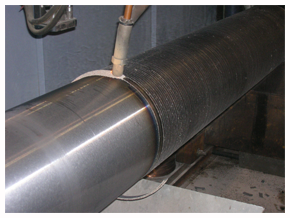

The Process of Fabrication

The production of stainless steel involves several key steps. Initially, the material is cut using methods such as shear, water jet, or laser cutting to ensure precise dimensions. Following the cutting process, the sheets are bent into the desired angles and shapes using press brakes and other bending equipment, preserving the material’s integrity. Finishing techniques, including passivation, coating, or polishing, are then applied to enhance the appearance and functionality of the stainless steel. These processes ensure that the final product meets both practical and aesthetic standards, resulting in a superior finish that enhances durability. The entire process is integral to stainless steel sheet fabrication, ensuring high-quality results.