If you operate a fabrication facility, you know the importance of cutting tools and related equipment. In fact, when it comes to metal fabrication of any type, cutting is one of the most significant steps. When you are producing parts and items, accurate cutting is imperative. This is why many fabrication shops employ laser cutting devices. This technology provides precise cuts at desirable speeds. However, it is important to select the right laser tool.

Choosing Optimal Laser Cutters

Laser cutters have been around for more than two decades now. Technology is constantly working to improve these devices. When selecting the right laser cutter for your shop, it is important to consider a variety of factors capable of affecting the ability for it to perform at its optimal level. Consider the following as a basis:

- Application: What does your shop plan to use it for?

- Accuracy: How accurate are the models under consideration? How precise do you need it to be?

- Efficiency: How efficient is the laser cutter?

- Speed: How fast a laser cutting machine do you require?

- Technology: What type would be better: CO2 or Fiber Technology?

- Energy Usage: How much power will the machine suck-up?

- Environment Compatibility: Does it fit well within the scope of the shop floor?

- Cost: Most lasers last 10 years. Be sure to purchase one that is cost-effective for this and any other projected time period.

You must also consider other aspects influencing the selection including software, training

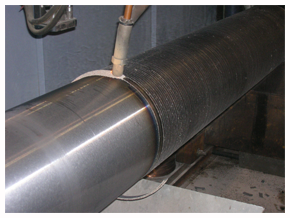

Laser Cutting Equipment

Laser cutters provide shops with the ability to slice quickly and accurately through diverse types of materials. For metalworkers, laser cutting can improve productivity and reduce overall production time. With new and improved laser technology offering different options and lasers lasting for a minimum of 10 years, prevent what could be a costly error. Consider carefully your options, making sure the choice your shop makes is the right one.