For industries looking to produce durable items, the need is to find a material capable of withstanding the stresses and environments in which it will function. Metal is the most common material of choice. To make it usable, manufacturers consult metalworkers. In particular, they rely on steel fabricators to produce the type of item they require.

Steel Fabrication

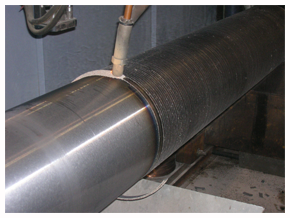

Steel fabrication involves taking a raw material, in this case, steel, and creating machinery and other devices and objects. Fabricators accomplish this through various techniques including cutting, bending, burning, machining and welding. The components they make are then available for a variety of industrial, commercial and even decorative applications.

Common Applications

Steel fabricators provide their products across a wide swathe of industrial sectors. Among their many customers are the following four sectors:

- Aerospace: Engineering aircraft of all types requires using steel. No matter whether the plane is for the military or for commercial use, metalworkers fabricate sections out of steel.

- Automotive: Globally, the consumption of steel by the transport sector is around 16%. The automotive sector uses a significant amount of this percentage – usually in the form of Advanced High-Strength Steel (AHSS).

- Construction: Structures of diverse types – ranging from bridges to skyscrapers, rely on structural steel to produce various steel sections, e.g. girders, beams, ladders, platforms.

- Mining: When it comes to the metal used for mining machinery, steel rules. Fabricated steel comprises such items as rails, rods, pipes and so much more.

Other applications include shipbuilding and different structures and components for the energy sector.

Steel Fabricators

Steel fabrication performs an essential role in many different industrial sectors. It provides components and products for everything from auto parts to mining tools. Praised for its durability and versatility, it is easy to see why steel fabricators find their products in great demand.