In all types of systems and applications, the ability to control the flow of the liquid, air, gas, or steam through the system is essential. Choosing the correct size, type, and options in a valve is critical to overall system performance and control.

There are many different types of valve styles to choose from. One of the specialized types of valves used in engines and motorized components is the poppet check valve, also known as the poppet or mushroom valve.

Unlike many other types of valves, the poppet check valve is designed to work completely automatically in the engine or system. They are most commonly used to control the amount of air or gas that is allowed into the engine for optimal performance.

The Design

The poppet check valve has a unique and distinctive design. It has a tapered plug, which is a shaft with a disc at the end, as well as a spring that controls the movement of the plug up and down in the motor or engine. The disc is shaped to conform to the interior surface of the engine component to create a seal and then to push up and out to allow gas or air into and out of the internal combustion motor.

It is critical for the valve face to seal correctly in the valve seat to maintain the efficiency of the motor. These valves are designed to withstand high pressure as well as the high temperatures that are found with internal combustion motors.

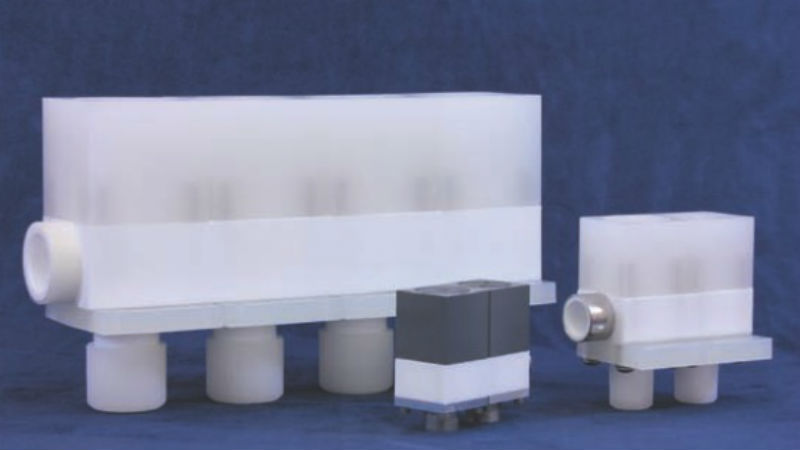

The same types of valves are also used in the control of sterile air in clean rooms and specific types of production methods. The valves can be found in pharmaceutical production as well as sanitary processes in food and beverage production among other types of similar applications.