Pneumatic valves are used in a compressed air pneumatic system. These valves help to ensure the precise control and safe use of these systems. These systems use fluid mediums and need precise control for the direction, velocity, and force of the medium.

Read on as we discuss the purpose of pneumatic valves and how they work.

Using Pneumatic Valves

Pneumatic valves are relatively easy to use. Most pneumatic systems have basic components like a filter regulator, an air tank, a compressor, and a lubricator. Additionally, these valves use compressed air to gain control of the airflow.

When working to control compressed air, pneumatic valves work efficiently to control the air in a pressure tank.

Using Pneumatic Valves for Air Preparation

Pressure relief valves are designed to control the pressure of a system by exhausting any excess pressure. These valves are often used in air storage devices to prevent excessive pressurization.

These safety valves or relief valves are crucial to the air preparation stage. As pressure regulators, these valves are used in a pneumatic system to limit the pressure by blocking the upstream force at the inlet.

Benefits of Pneumatic Valves

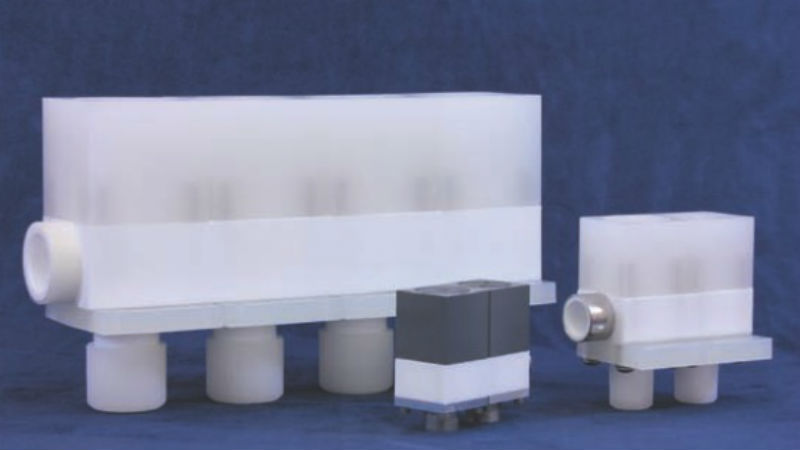

Whether you’re using miniature pneumatic valves or a spring offset valve, these tools all play an essential role in your pneumatic system. When it comes to the benefits of miniature valves, the smaller size is ideal for systems with limited space.

Likewise, pneumatic valves of every kind are versatile and can be used for various configurations. Other benefits of these types of valves include affordability, durability, and corrosion resistance.